Before choosing which diamond discs best cut porcelain stoneware, let’s talk about their parts, the types, and the differences between them.

Diamond discs: parts, types and differences

The “cut” that diamond discs make is thanks to the friction of the diamond particles they contain, but where are these particles found inside the disc?

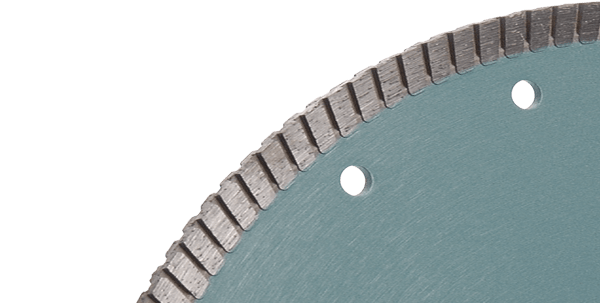

To put you in the situation, the highlights of a diamond blade are the hardened steel plate, and the segments or edges of the blade where the different compositions of metal powders and diamond grains are mixed, pressed and sintered.

These diamond particles, located in the segments, are held together thanks to the binder that surrounds them and, on their resistance to abrasion, the useful life of the blade will depend, as well as whether the cut is more or less fast and perfect.

Therefore, as the material is cut with the disc, it is the material itself that is wearing down the disc, specifically the binder and therefore the diamond particles.

And how do you get the union between the steel plate and the segments to form the disc? Through silver brazing or laser welding. The difference in making one or the other is in the type of cut you are going to make with the disc.

In the case of dry cutting, it is better to use laser welding, as it is much safer and more solid. Whereas, if you do the wet cut, you could join it with either of the two types. Normally, silver brazing is used to make standard discs.

There are a large variety of diamond discs. What do you need to know to distinguish them?

As you know, there are many diamond discs and therefore, there are some points that you should take into account to know which one to choose according to the hardness and abrasiveness of the material to be cut; speed, depth and finish of cut you are looking for.

First, the edges of the disc segment can be:

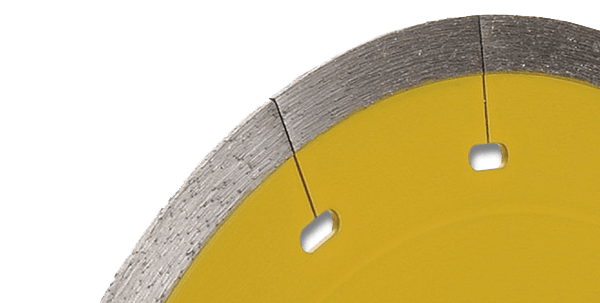

- Continuous when you are looking for a finer finish with a not very fast cutting speed as in the case of ceramic materials, where you want the finish to be perfect.

- Segmented when you are looking for a much faster cutting speed in exchange for a less fine finish. Segment performance will be optimal.

- Turbo when you are looking for a finish and average speed compared to the other two.

And depending on the type of cut you make; the discs will be specific for:

- Wet cutting when you are going to use the machine for a long time, need to cool with water, and the cutting is deeper.

- Dry cutting when the welding of the disc is laser and heat resistant, that is, it does not need water to cool down and the cut is straight and not very deep.

And finally, the diameter of the blade is also important, depending on the machine you are going to use and the depth of cut you are looking for. The larger the diameter, the greater the depth; contrary to the speed of the disk in operation which should be slower.

- On 115, 125 and 150 mm mini-grinder discs, on 180/230 mm large grinder, on 180/210/230/300/315 mm cutting table; and in joint cutter and bridge machine up to 3500 mm.

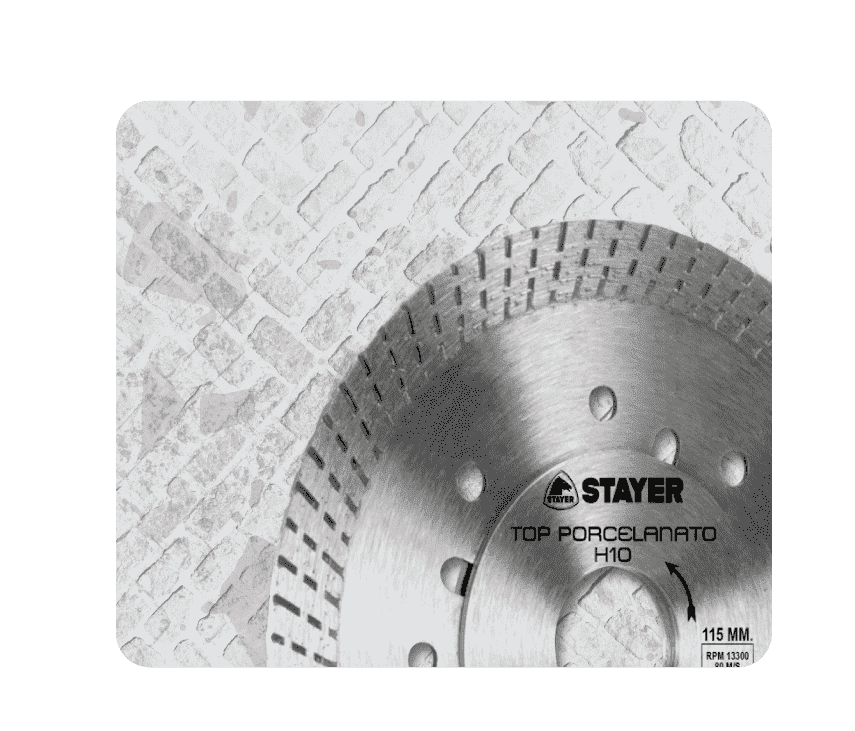

What are Stayer’s best diamond discs for cutting porcelain stoneware?

At Stayer, we have a line of porcelain-specific discs.

Considering that porcelain materials are very hard materials, but not abrasive, we manufacture diamond discs that are sharp enough to cut the material, but with an unsused agglomerate to make cutting faster and of good quality.

Within our line we differentiate two ranges, the Professional, and the Platinum. The difference between the two is that the Platinum range has higher-height segments, which means that these discs will have higher performance and last longer.

Next, we’ll show you 8 types of discs with their differences and characteristics depending on the Segment, material and tool to cut with.

LÍNEA PLATINUM

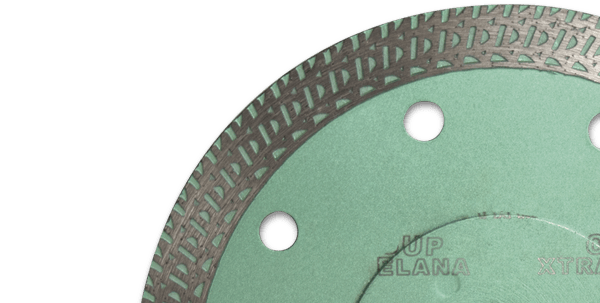

First, the Turbo Extrafine Platinum, with an extra-fine, continuous and crenellated segment; and of height H7, presents a perfect finish thanks to its diamond crown. It is used for cutting porcelain stoneware, ceramic tiles, tiles, granite and Klinker, and is used with angle grinders, cutters and cutting tables.

Secondly, the Super Turbo Extrafino Platinum has a continuous and crenellated segment but with a height of H10. It has an optimum cutting finish on stoneware and porcelain stoneware. It is suitable for cutting ceramic materials in general and is used with angle grinders.

And finally, the Top Porcelain Platinum. With a continuous and crenellated segment, height H11, has a high cutting speed and a perfect finish thanks to its new diamond coating technology. It is used to cut porcelain stoneware and ceramic materials in general, and is used with angle grinders.

LÍNEA PROFESIONAL

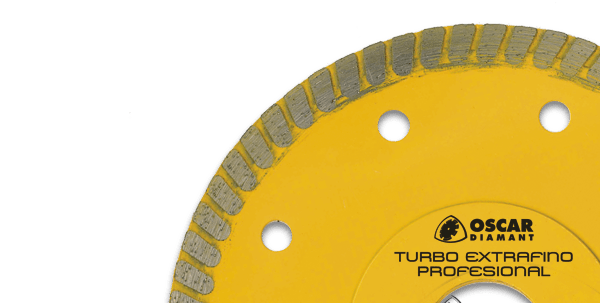

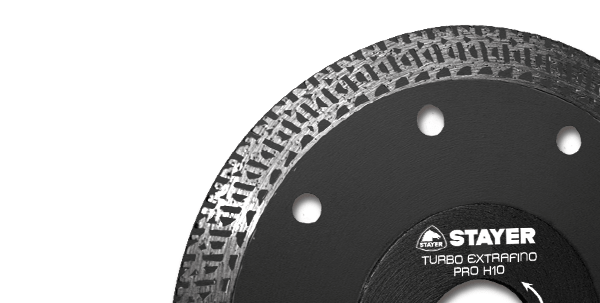

In this line, we find in first place the Turbo Extrafino Pro disc. It has a turbo segment with H7 height, as well as a medium cutting speed and finish. It is used for cutting porcelain stoneware, vitrified ceramic and granite, and is used with angle grinders.

Next is the Turbo Extrafino Pro H10. It has a turbo segment, height H10, with a medium cutting speed and finish. It is used to cut porcelain stoneware, vitrified ceramic and granite and is used with angle grinders.

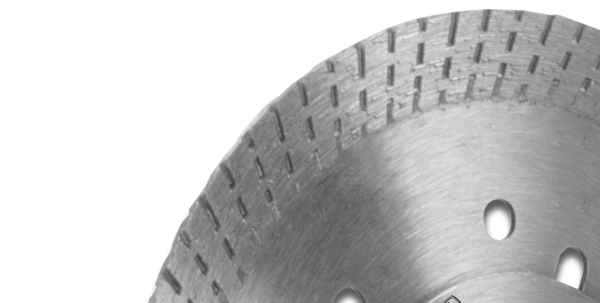

On the other hand, the Turbo Huracán. It has a continuous and crenellated segment, height H10 and H12, and has a greater thickness of plate and segment to improve resistance to torsion and to be able to cut very hard materials such as porcelain stoneware, granite, kliker, ferrogrés, dekton and silestone. It is used with angle grinders.

Next, the Porcelánico Banda continua. It has a continuous segment, height H7, and presents an optimal cutting finish in ceramic materials. It is used to cut porcelain, vitrified ceramic, marble and artificial compact stones and is used with angle grinders, cutters or cutting tables.

And finally, the Porcelánico segmentado. It has a segmented segment, height H7, with a continuous band and makes “J” shaped cuts to improve cooling and extend service life. It is used to cut porcelain, vitrified ceramic, marble and artificial compact stones; and it is used with angle grinders, cutters or cutting tables.

Which of our models do we recommend for cutting porcelain stoneware?

Of each of the blades that we have at Stayer, we highlight our Turbo Huracán because thanks to its 2-2,6 mm thick sheet you can cut very hard materials such as klinker, stoneware, ferrogres, dekton and silestone, among others. And, in addition, it is very well cooled by the perforations in its plate.

But to cut ceramic materials such as porcelain stoneware we recommend the Super Turbo Extrafino and the Top Porcelanico from our Platinum range because they achieve a perfect cut finish at a very high speed.

It’s your turn. Which one do you prefer?