Each of the existing ceramic materials has specific particularities in terms of composition and manufacture. Both porosity and resistance or durability are some of the conditions that can mark the difference when choosing which one to use depending on the application we are looking for. Therefore, more and more construction professionals recommend the use of porcelain stoneware compared to other types of ceramic materials.

And, what is this due to? To the advantages it presents.

What are the advantages of porcelain stoneware?

Thanks to its high density and low porosity it shows greater resistance to impacts, wear and temperature changes, as well as less absorption of liquids. Therefore, its adaptation of color and shape according to the space in which you want to place (indoor or outdoor surfaces, countertops, walls, facades, among others) is wider.

For all this, it is also important to know what the correct tools are and how to use them, to drill porcelain stoneware and to obtain the best result.

What is the right tool to drill porcelain stoneware and get the best finish?

In the case of ceramic materials in general, the ideal for drilling is the use of drill bits. These will vary depending on the material, the diameter you are looking for and the surface where you are going to drill (fixed or mobile).

Therefore, depending on the material, we can classify them into:

- Widia tipped lance bits: for drilling glass and ceramic tiles.

- Widia drill bits: for drilling small diameters in tiles and masonry.

- Tungsten carbide bits: for drilling large diameters in tiles and masonry.

- Wet-cut electroplated diamond bits: for marble.

- Vacuum Brazed diamond bits: for stoneware, porcelain stoneware, granite, the use of dry-cut .

As for the diameter of the drill bit, it can vary between 5 to 120 mm depending on the drilling size you are looking for.

If the perforations are with diameters:

- Greater than 12 mm: in ceramic materials you can opt for: diamond drill bits, specifically Vacuum Brazed diamond drill bits, if the ceramic materials are very hard, because:

- They drill faster.

- They are more abrasion resistant and the finish is much higher quality than the previous ones.

- And vibrations decrease on surfaces that aren’t fixed.

- Less than 12 mm: in soft ceramic materials you can opt for: Widia drill bits, wet cut, electroplated diamond drill bits or diamond drill bits.

- Between 12 and 120 mm: in hard ceramic materials with wet cut, electroplated core bits, or dry cut Vacuum brazed diamond core bits.

In short, as we can see, in the case of porcelain stoneware the ideal for drilling is to use a diamond drill bit since, being a very hard ceramic material, another type of bit, such as Widia, could cause the loss of the edge quickly and prolong the drilling time.

As the goal you are looking for is to achieve the best finish, in the shortest possible time, in Stayer, we recommend the use of the Vacuum Brazed diamond drill bit for porcelain.

As far as there are different bit diameters you should also consider which one to use with drill or grinder.

- For small diameters and when drilling on wall: drill.

- For large diameters and on non-fixed surfaces: grinder.

In the following sections we will explain, in more detail, both when to use drill or grinder and why to choose a Vacuum Brazed diamond drill bit.

When should I use a grinder or drill to drill porcelain stoneware with diamond drill bits?

« So, at this point, which one do I choose, drill or grinder? »

The choice will depend on both the diameter of the drill bit and the surface where you are going to drill.

Drill

For drill diameters of 5, 6, 8, 10 and 12 mm to avoid drilling at high r.p.m´s. Although we must emphasize that thanks to the M14 insert adapter to hexagonal shank that the bits have, which are exclusively for use with a grinder, they can also be used with a drill.

For perforations of tiles or porcelain stoneware on the wall (such as bathrooms and kitchens) as it is much more comfortable.

And in case of using wet cut electroplated diamond drill bits, because as we mentioned above, they need to work at low revolutions, and it is necessary to refrigerate them with water.

Grinder

For bit diameters between 5 to 120 mm (specified in the product data sheet), because in larger diameters it helps you drill at high r.p.m´s and therefore improve the performance of Vacuum Brazed diamond bits.

For porcelain stoneware perforations on surfaces that are not fixed. Specifically, an angle grinder as it reaches the high speeds that require such drilling.

And in case of using Vacuum Brazed diamond drill bits in dry cut, because they work at high r.p.m´s and have higher performance and fast cutting.

Why should I choose a Vacuum Brazed diamond drill bit to drill porcelain stoneware?

« You would say, why should I choose Stayer’s Vacuum Brazed diamond drill bits to drill porcelain stoneware and not a common one? »

The answer is simple:

Thanks to the “vacuum brazing” technology with which we manufacture it:

- The bit life is longer.

- It manages to increase the retention of diamond grains, thus reducing both friction and temperature.

- Cutting is faster.

- Drilling very hard materials such as porcelain stoneware, or others such as marble or granite, is much simpler.

- In addition, by allowing dry cutting, it is very useful for wall drilling as it does not require water cooling.

- You get a perfect finish.

How should I use stayer’s vacuum brazed diamond drill bits?

- Before starting it is advisable to equip yourself with protective equipment, glasses, gloves and masks.

- Then choose the bit size and the use of drill or grinder, according to the criteria we explained above.

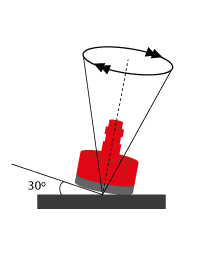

- To begin with, the bit must be positioned at an angle of between 30-45 degrees with respect to the material to be drilled.

- It should be noted that movements must be oscillating to facilitate the core bit placement and obtain greater accuracy during drilling, prevent the core bit from slipping, helping to evacuate dust and preventing premature wear of the bit.

- And at the end of the drilling, you must wait for the machine to stop completely. Remember to remove the remaining material in order to continue.

Tips for you to get the most out of stayer’s vacuum brazed diamond drill bits

For you to get more performance out of Stayer Vacuum Brazed diamond drill bits, and therefore extend their service life it is recommended that:

- Use a grinder with electronic speed regulator, such as Stayer SAB 1351 CS/ SAB 1301 E, because you can adjust the speed to the diameter of the bit you are already using.

- If the perforations are continuous, cool the drill bit. How can you do it? With the machine running at no load speed for 1 minute or leaving it standing until the bit temperature drops.

- If you use 5, 6, 8, 10, and 12 mm bits, use the specific Stayer cold wax.

- If you use drill it is advisable to help you with the guide with drill suction cup so that the bit does not slip, and the finish is perfect.

SAB 1351 CS

With each of these guidelines, we are confident that you will be able to drill ceramic materials, such as porcelain stoneware, with an optimal finish and quickly. All this thanks to the cutting of the Vacuum Brazed diamond drill bits from Stayer.

If you want to not miss any steps to follow to get the best drilling result, in the next video you will see the process step by step.