In order to adapt to all the needs of professionals in the industrial and wood sector, we have several models of Stayer mitre saws.

These mitre saws can be with an upper cutting table or telescopic, induction motor or brushes; belt transmission; laser guide or tilt to one side or both.

And that is why, depending on the factors that influence your project, it is recommended that you choose it with some characteristics or others. And for you to choose well I am going to show you the differential and common elements that they have in addition to the types that we offer. So, let’s go!

What types of Stayer mitre saws we have?

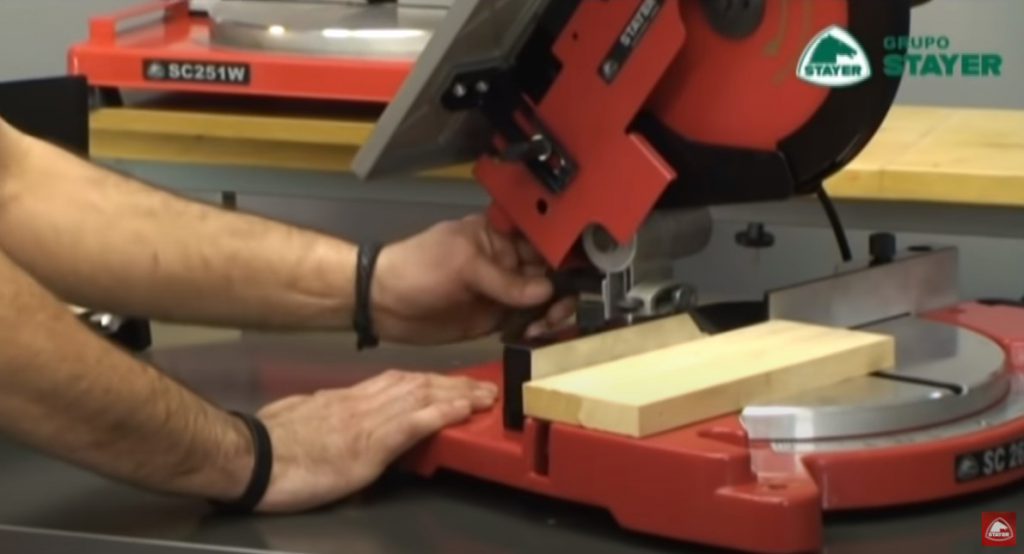

Stayer mitre saws are tools that will allow you to cut straight or mitre wood or other materials such as aluminum or PVC. And the most widespread uses are for skirting angles, door frames or furniture.

At a general level, there are two types: combined with an upper cutting table and telescopic. The first ones will have a cutting table at the bottom and another at the top, while the telescopic ones will not. The latter have a tilting head with a large cutting capacity in length.

They can also have brush or induction motor and even belt transmission. Being those of induction motor quieter than those of conventional motors, especially if they include transmission by belts, since when they are turned on they take a little longer to reach the maximum motor torque (that is, you have to wait a few seconds before starting to cut and do it at full speed) and therefore, the only noise you will hear is the spinning of the disc.

And although they differ in more components, they also have a series of common elements so that they are effective and safe when working. I will show them to you with our SC 2600 W model.

What common elements have Stayer mitre saws?

Common elements of the lower cutting tables

In the lower cutting tables the common elements that they will have, to a greater or lesser extent, are the plate, the disk protection casing, the tilting motor, and the fixing clamp.

Base

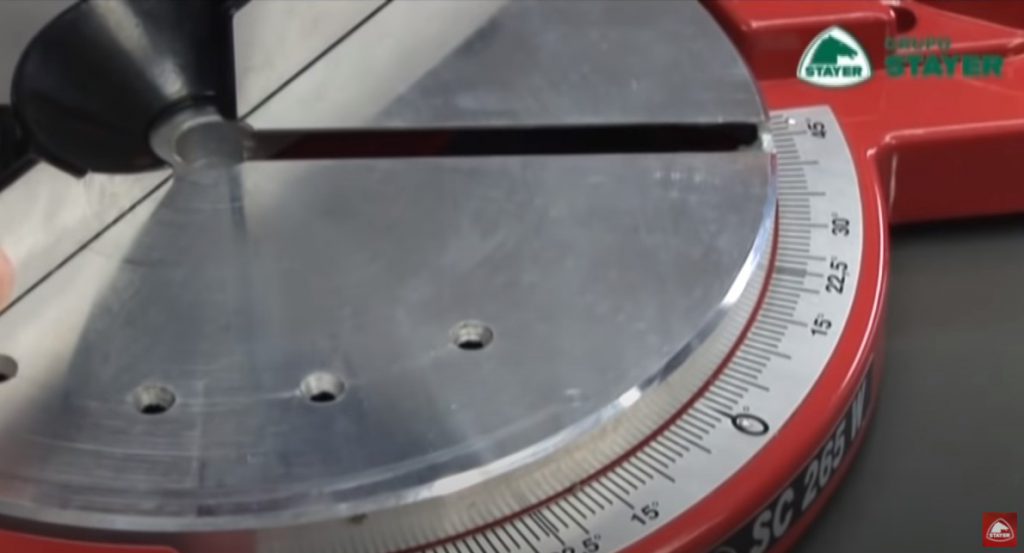

The base is rotatable and has a scale for horizontal mitre angles with which you can adjust the cut in the position you want. And in the middle of the base the horizontal anchor bolt for fixed mitre angles together with the horizontal interlock side buttons for discretionary mitre angles. With them you will secure the base in the position you want so that the cut is much safer.

Disc protection casing

The disc protection guard is meant to prevent material debris from accidentally getting between the disc teeth when you are using the upper cutting table. Along with clamping knobs for easy removal when cutting with the lower table. And the pendular protective cap on the disc holder (which will be progressively removed, exposing the tooth when cutting).

Tilting motor

The motor can be tilted thanks to the vertical locking lever for optional mitre angles.

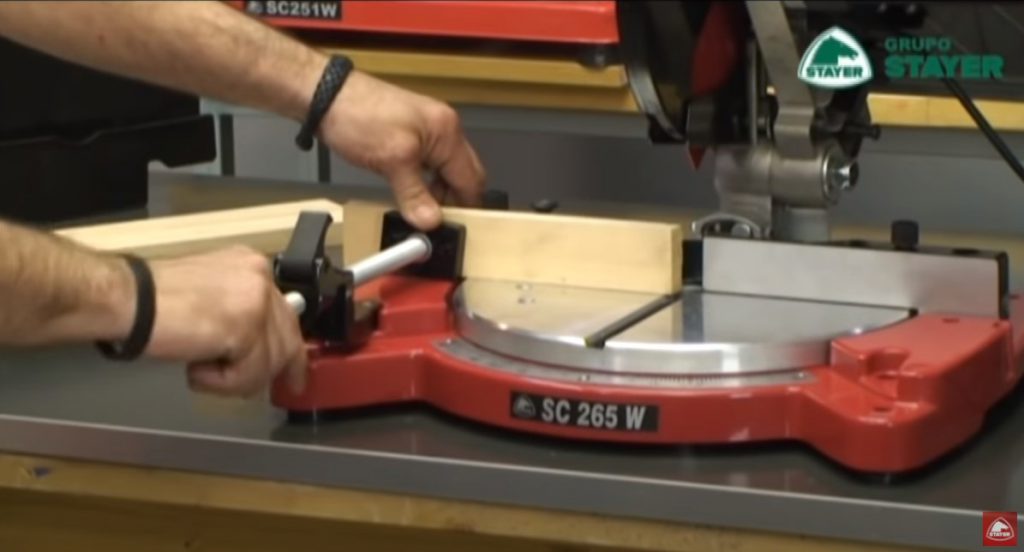

And the fixing clamp

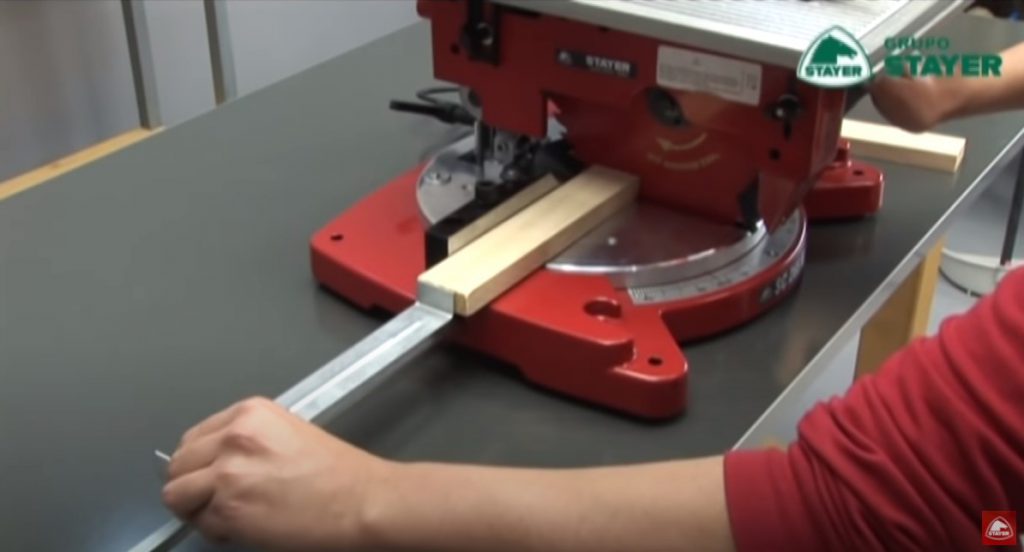

The fixing clamp to anchor the pieces to be cut and a lateral cutting guide to cut the pieces with the same measure without having to be measuring one after another.

Common elements of upper cutting tables

However, only mitre saws combined with an upper cutting table will have an upper table made up of:

The upper side guide to measure the distance between the guide and the disc.

Two knobs for adjusting the height of the upper table.

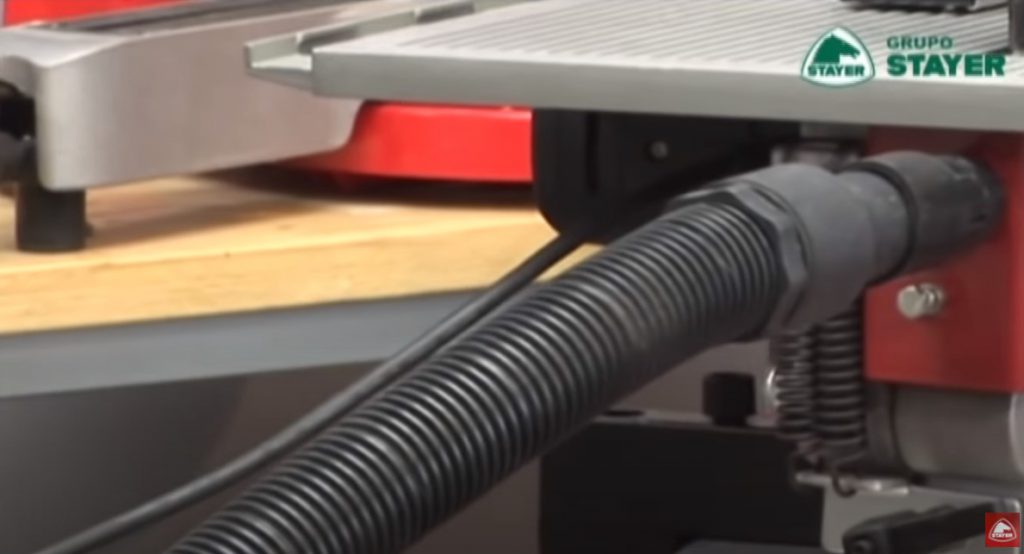

And a cutting particle ejection nozzle where you can adapt a vacuum cleaner to keep everything clean during work.

Telescopic Mitre Saw Top Elements

Therefore, the telescopic mitre saws that will not have an upper table, will have a tilting arm with the head to couple the cutting disc.

What models we offer you according to your selection criteria?

After knowing the common elements of Stayer mitre saws, it is time for you to know the types we offer to cover all your needs.

- To adapt the blade to the size you need: 210, 254, 305 and 315 mm diameter mitre saws. And, depending on the material and finish you are looking for, we have a variety of cutting discs with different characteristics.

- For cutting long pieces, such as skirting boards: mitre saws with telescopic arm.

- Depending on the hardness of the material: variable electronic speed mitre saws.

- If you need a light machine to transport easily: mitre saws with sheet metal or aluminum tables.

- To make it quieter: belt transmission mitre saws.

- Depending on the job requirement: mitre saws with brush motors and induction motors.